Since 1974, Cooper Stairworks has masterfully blended centuries-old stair building techniques with state-of-the-art design and construction. Our preassembled staircases offer the perfect combination of elegance, strength, and cost-effectiveness, tailored to meet the expectations of even the most selective buyers.

Ready to learn more? View our brochures and catalogs.

PLEASE CONTACT ME ABOUT MY STAIR PROJECT:

WHY CHOOSE COOPER PREASSEMBLED STAIRS?

EFFICIENCY

Our preassembled staircases are designed for fast and accurate installation, significantly reducing jobsite labor and saving you time and money.

QUALITY

Starting with the finest kiln-dried lumber, we utilize old-world joinery techniques, cutting-edge technology, and innovative production methods to deliver stairs that exceed the quality expectations.

VERSATILITY

From simple and safe utility stairs to stunning, curved designs for grand foyers, our expert stair builders create solutions that enhance any space.

TRUST

Benefit from locally crafted stairs, expert staff assistance, and our commitment to standing by our products long after they leave our woodworking shop.

INSPIRATION GALLERY

Explore the beauty and craftsmanship of Cooper Stairworks. Click below to explore and get inspired!

Cooper Preassembled Staircases set the standard for efficient stair building. Our streamlined production process in our Somerset, MA woodworking shop ensures expertly crafted stairs that save time and resources during installation on-site.

5 Year Warranty

Cooper Stairworks proudly offers a five-year warranty to the original purchaser, covering defects in material or workmanship on our preassembled staircases.

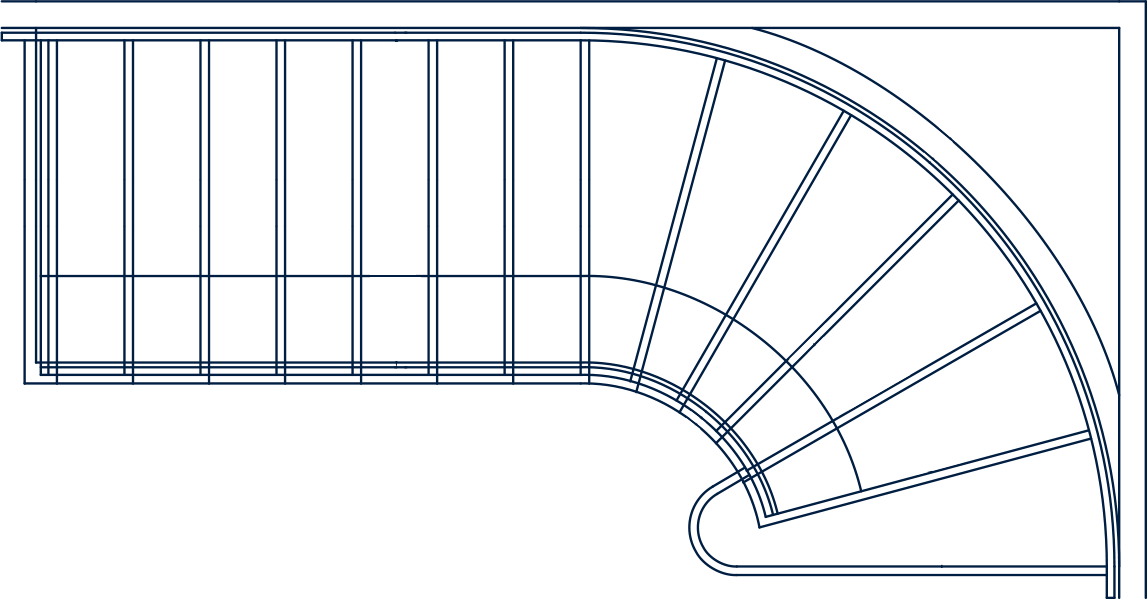

CAD Support

Not all stair projects require CAD support, but when necessary we provide very detailed drawings of the project for review.

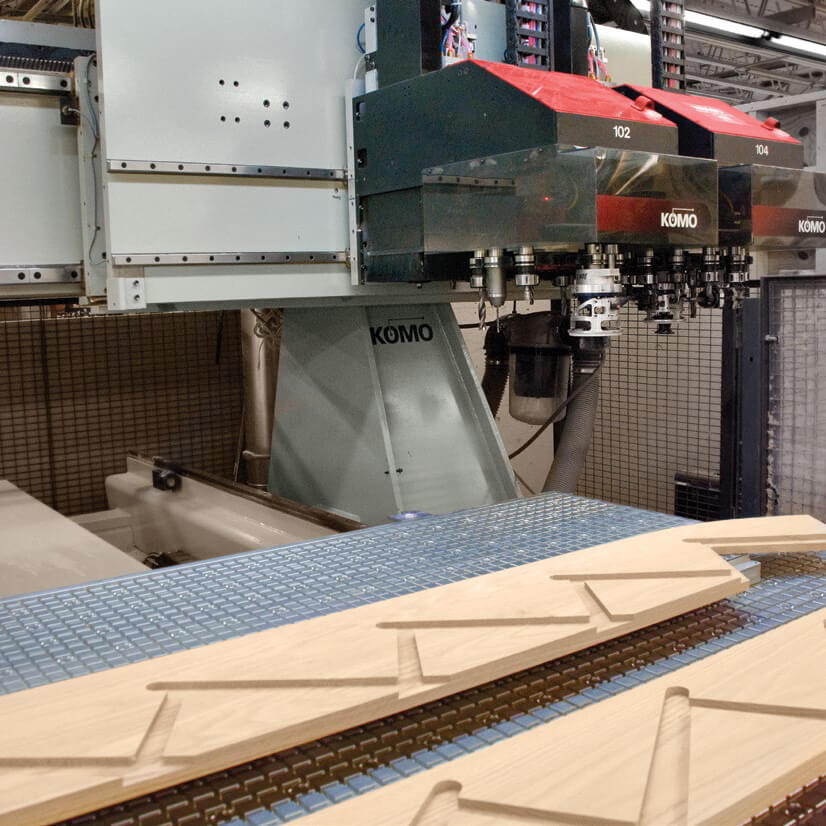

State-of-the-Art Technology

We have invested in the latest technology available. Automatic stair design software is used to support two CNC routers with 4 and 5 axis machining capabilities.

Tongue & Groove Construction

This superior method of assembly creates a sure fit for the riser to the tread and virtually eliminates squeaks.

Notched Newels

With our prefit rail system, all newels are notched to the proper height to comply with code in conjunction with the rail system. They are dry fitted and marked for location.

ZIPBOLT UT Rail Bolt

All our rail joint connections are made using the ZIPBOLT™ UT Rail bolt. Easier, Faster, and Stronger. Tighten joints in seconds.

Threaded Inserts

On wooden, turned, tapered-top balusters, we use a threaded insert in the tread and a machine/lag screw in the baluster for superior strength and ease of installation.

Blind Fasteners

When we apply a return to a stair tread, all work is done on the backside so fasteners are never visible on the finish face and edge of the tread.

Fas-N-Fast

A strong machine screw style connector is used to connect all pin bottom newels to the starting step.

Packaging

The stair is wrapped in clear plastic with custom water resistant double thick cardboard tread and riser guards applied for protection during construction.

Plywood Templates

Plates are provided for framing balcony sections and supporting walls. Stairs are assembled back in our shop using exact duplicates of these templates.

Easy Installation

As soon as the project is weather tight, the stair is normally installed in less than half a day so it can be used during the construction process.

SOMERSET, MA

Flagship Showroom, Corporate Offices, Production Facility:

1255 Grand Army Highway

Somerset, MA 02726

Tel: 508-679-6479 / 800-543-5403

Fax: 508-235-4434

Showroom Hours:

Monday-Friday:

7:30am to 5pm

Saturday by appointment only.

Kitchen Design Center:

Monday-Friday:

9am to 4pm

Saturday by appointment only.

SOUTHBORO, MA

Showroom:

Southboro, MA 01772

Tel: 508-481-9774

Fax: 508-229-8179

Showroom Hours:

Monday-Friday:

8am to 3pm by appointment only.

PEMBROKE, MA

Showroom:

55 Corporate Park Drive

Pembroke, MA 02359

Tel: 781-826-7770

Fax: 781-829-4254

Showroom Hours:

Monday-Friday:

8am to 4:30pm

Additional hours available by appointment.

INSPIRATION GALLERY

STAIRS GALLERY QUICK LINKS: All Stairs // Curved Stairs // Cable Rail // Glass Rail // Box Newels // Spiral Stairs

- 179_010

- 179_009

- 179_008

- 179_007

- 179_006

- 179_004

- 179_003

- 179_002

- 179_001

- 065_001

- 180_013

- 180_012

- 180_011

- 180_009

- 180_008

- 180_007

- 180_006

- 180_004

- 180_003

- 180_002

- 180_001

- 178_008

- 178_007

- 178_006

- 178_004

- 178_003

- 178_002

- 178_001

- 180_013

- 180_012

- 176_017

- 176_018

- 176_019

- 176_020

- 176_021

- 176_029

- 175_006

- 016_013

- 016_033

- 016_032

- 171_012

- 171_011

- 171_010

- 171_009

- 171_008

- 171_006

- 171_004

- 171_003

- 171_002

- 170_008

- 170_007

- 170_006

- 170_005

- 170_004

- 170_003

- 170_002

- 170_001

- 166_008

- 166_007

- 166_006

- 166_005

- 166_004

- 166_003

- 166_002

- 166_001

- 165_010

- 165_009

- 165_008

- 165_001

- 164_016

- 164_015

- 164_014

- 164_013

- 126_007

- 168_005

- 168_004

- 168_003

- 168_002

- 168_001

- 167_013

- 167_012

- 167_011

- 167_010

- 167_009

- 167_008

- 167_007

- 167_006

- 167_005

- 167_004

- 167_003

- 167_002

- 167_001

- 163_012

- 163_011

- 163_010

- 163_009

- 163_008

- 163_007

- 163_005

- 163_004

- 163_003

- 163_002

- 163_001

- 161_018

- 161_017

- 161_009

- 156_007

- 156_002

- 155_001

- 154_008

- 154_005

- 153_004

- 152_002

- 151_001

- 150_004

- 150_002

- 150_001

- 148_003

- 148_001

- 147_005

- 143_004

- 143_003

- 143_001

- 138_006

- 136_014

- 135_003

- 135_001

- 134_004

- 134_003

- 134_001

- 133_003

- 133_001

- 132_005

- 132_003

- 132_002

- 130_004

- 128_001

- 127_005

- 127_003

- 126_005

- 124_001

- 123_003

- 123_002

- 123_001

- 139_003

- 139_001

- 119_002

- 114_006

- 114_004

- 113_010

- 113_009

- 113_008

- 109_008

- 109_003

- 108_006

- 108_003

- 108_002

- 106_007

- 106_006

- 106_001

- 105_004

- 105_003

- 103_001

- 102_003

- 101_007

- 101_005

- 101_003

- 119_003

- 098_016

- 098_011

- 097_007

- 097_001

- 096_007

- 096_005

- 096_002

- 095_002

- 093_004

- 063_002

- 063_001

- 062_002

- 061_003

- 061_002

- 061_001

- 060_003

- 060_002

- 060_001

- 059_001

- 058_003

- 058_002

- 058_001

- 057_001

- 056_002

- 056_001

- 055_003

- 055_002

- 055_001

- 054_001

- 053_001

- 052_001

- 099_003

- 049_003

- 049_002

- 049_001

- 048_001

- 047_021

- 047_020

- 047_019

- 047_018

- 047_017

- 047_016

- 047_015

- 047_014

- 047_013

- 047_012

- 047_011

- 047_010

- 047_009

- 047_008

- 047_007

- 047_005

- 047_004

- 047_003

- 047_002

- 047_001

- 045_001

- 044_002

- 044_001

- 043_002

- 043_001

- 042_005

- 042_004

- 042_003

- 042_002

- 042_001

- 041_001

- 040_001

- 039_002

- 039_001

- 038_001

- 037_002

- 037_001

- 036_001

- 035_004

- 035_003

- 035_002

- 035_001

- 034_001

- 033_007

- 033_006

- 033_005

- 033_004

- 033_003

- 033_001

- 032_002

- 032_001

- 031_001

- 050_001

- 049_006

- 049_004

- 030_007

- 030_006

- 029_005

- 029_002

- 029_001

- 028_001

- 027_002

- 027_001

- 026_005

- 026_002

- 026_001

- 025_002

- 024_001

- 022_008

- 022_002

- 021_011

- 021_010

- 021_009

- 021_008

- 021_003

- 030_008

- 020_017

- 020_014

- 019_015

- 019_008

- 019_005

- 018_015

- 018_014

- 018_004

- 018_003

- 018_001

- 017_005

- 017_004

- 017_003

- 017_002

- 015_001

- 014_003

- 014_002

- 014_001

- 013_011

- 013_008

- 002_009

- 002_006

- 002_001

- 003_010

- 179_010

- 179_009

- 179_008

- 179_007

- 179_006

- 179_004

- 179_002

- 179_001

- 065_001

- 180_013

- 180_012

- 180_011

- 180_009

- 180_008

- 180_007

- 180_006

- 180_004

- 180_003

- 180_002

- 180_001

- 180_013

- 180_012

- 016_033

- 016_032

- 171_012

- 171_011

- 171_010

- 171_009

- 171_008

- 171_006

- 171_004

- 171_003

- 171_002

- 171_001

- 126_007

- 168_005

- 168_004

- 168_003

- 168_002

- 168_001

- 135_003

- 133_003

- 133_001

- 127_005

- 126_005

- 119_002

- 114_006

- 114_004

- 101_003

- 119_003

- 060_002

- 060_001

- 058_003

- 058_002

- 052_001

- 048_001

- 047_021

- 047_018

- 047_016

- 047_015

- 047_014

- 047_007

- 047_005

- 047_003

- 047_001

- 045_001

- 044_002

- 044_001

- 043_002

- 043_001

- 042_004

- 042_003

- 042_002

- 042_001

- 040_001

- 039_002

- 039_001

- 038_001

- 037_002

- 037_001

- 036_001

- 035_003

- 035_002

- 034_001

- 033_007

- 033_006

- 033_005

- 033_004

- 033_003

- 033_001

- 032_002

- 031_001

- 030_007

- 030_006

- 029_002

- 029_001

- 028_001

- 027_002

- 026_005

- 025_002

- 024_001

- 030_008

- 018_014

- 018_003

- 018_001

- 015_001

- 167_013

- 167_012

- 167_011

- 167_010

- 167_009

- 167_008

- 167_007

- 167_006

- 167_005

- 167_004

- 167_003

- 167_002

- 167_001

- 163_012

- 163_011

- 163_010

- 163_009

- 163_008

- 163_007

- 134_004

- 134_003

- 134_001

- 115_001

- 017_005

- 017_004

- 017_003

- 017_002

- 003_003

- 003_017

- 003_016

- 003_010

- 016_006

- 170_008

- 170_007

- 170_006

- 170_005

- 170_004

- 170_003

- 170_002

- 170_001

- 166_008

- 166_007

- 166_006

- 166_005

- 166_004

- 166_003

- 166_002

- 166_001

- 163_005

- 163_004

- 163_003

- 163_002

- 163_001

- 044_002

- 044_001

- 175_006

- 016_013

- 016_033

- 016_032

- 161_017

- 161_012

- 161_009

- 160_004

- 160_003

- 156_007

- 156_002

- 154_008

- 154_005

- 152_002

- 150_004

- 150_001

- 148_003

- 148_001

- 147_005

- 143_004

- 143_003

- 143_001

- 138_006

- 136_014

- 135_001

- 132_005

- 128_001

- 124_002

- 124_001

- 123_003

- 123_002

- 123_001

- 139_003

- 139_002

- 111_001

- 108_006

- 108_003

- 108_002

- 106_007

- 106_006

- 106_001

- 105_004

- 105_003

- 105_002

- 102_003

- 098_016

- 097_007

- 097_001

- 095_002

- 093_004

- 055_003

- 055_002

- 055_001

- 054_001

- 053_001

- 049_003

- 049_002

- 048_001

- 047_020

- 047_019

- 047_010

- 047_009

- 047_004

- 041_001

- 040_001

- 034_001

- 031_001

- 049_006

- 026_005

- 026_002

- 026_001

- 021_011

- 021_010

- 021_009

- 021_008

- 021_003

- 020_017

- 020_014

- 019_008

- 019_005

- 018_015

- 018_014

- 018_004

- 018_003

- 018_001

- 014_003

- 014_002

- 013_011

- 013_008

- 013_003

- 002_001

- 139_001

- 035_004

- 035_001

- 049_006

- 049_004

- 026_002