- By Melissa Tavares

- In Horner Blog

- Tags Millwork, Mouldings

Our 6 Most Popular Moulding Profiles

Providing both form and function throughout the home, interior mouldings create a clean transition where the drywall meets the doors, windows, and floors, but perhaps more importantly they add architectural interest and texture to a space. Did you know that many of the patterns and proportions of today’s modern-day mouldings date back to the architectural columns of antiquity? Casings, crowns, and base mouldings have their roots in the past, but are essential elements in residential architecture today.

At Horner Millwork we have nearly a hundred different moulding profiles in stock, or we can custom-make virtually any profile in a spectrum of wood species. With so many patterns and profiles to choose from, the options can seem overwhelming. Below we have compiled our 6 most popular moulding profiles of 2017 to give you some insight on what is in demand today.

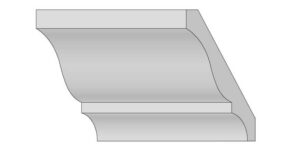

It’s great to see that a crown moulding is in one of our top spots! Crown moulding was once considered a luxury, but today’s savvy home builders know that a small investment in crown moulding can make a big impact on the look and feel of a home. WM47 Crown moulding is the perfect size for standard 8-foot walls, it leaves enough wall space between typical 6’8″ doors (with 3-1/2″ casing) and the bottom of the crown.

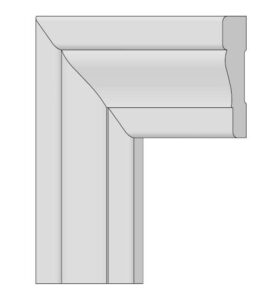

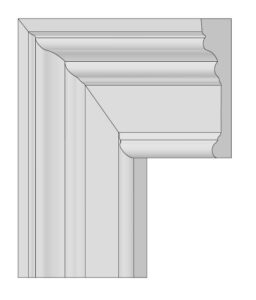

Inspired by classic colonial patterns, windsor casing has gained popularity over the past 15 years. Its traditional details make it perfect for New England style homes. A 3-1/2″ casing is usually a good choice for 8-foot high walls — giving windows and doors a pronounced frame without crowding the crown moulding above.

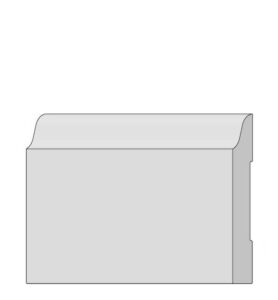

This traditional duo continue to be popular choices in modest homes throughout our region. When clam shell casing and baseboard lost favor in the late 1970s, colonial casing and baseboard became mainstream. When budget is paramount, narrower patterns like colonial casing and colonial base moulding are often used. However, our sales staff likes to encourage our customers to upgrade to wider and more beefy options when possible. The labor costs to install wider mouldings are virtually the same, so we suggest that instead of choosing 2-1/2″ casings and 3-1/2″ base mouldings, a small upgrade to 3-1/2″ casings and 5-1/4″ base mouldings make a much bigger impact on the space for a moderate increase in the cost of materials.

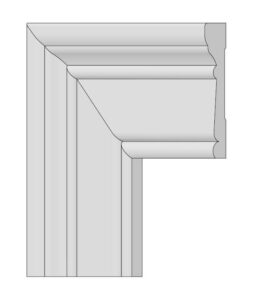

Stafford is our most popular window and door casing. We love this moulding for its strong backband and its double bead.

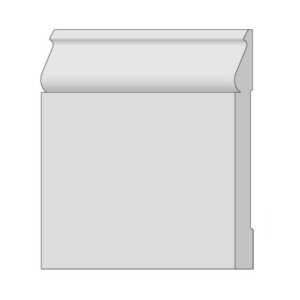

Finally, our most popular moulding is 5-1/4″ speed base! It’s very interesting that this moulding has risen to our top spot, given that you’d be hard pressed to find this moulding in homes built as recently as the early 1990s. Did you know that speed base received its name for its ease of installation? Before speed base was introduced to the market, carpenters would have to install a piece of flat stock moulding with a base cap on top to achieve this same look. Speed base is a 2-in-1 solution making it quick and easy to install. At a thickness of 9/16″, speed base is also fairly thin and doesn’t require a plinth block when it meets standard 11/16″ thick door casing, further making it a great cost and time saving choice.